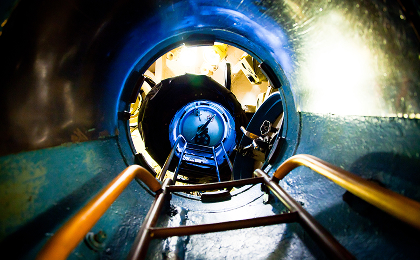

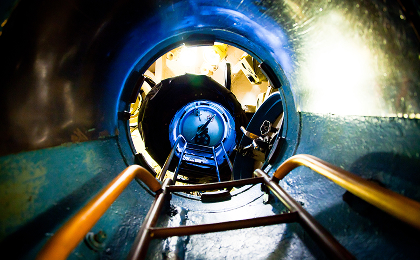

6G Welding & Chilled Water Pipe Rectification Works

QATCO Imaging Service has recently embarked on a critical project involving 6G welding and chilled water pipe rectification works, demonstrating our commitment to precision and excellence in the field of industrial services. This project encompasses a series of intricate task aimed at enhancing the integrity and functionality of chilled water pipelines, essential for various industrial processes.

The focal point of this endeavor is the implementation of 6G welding techniques, recognized as one of the most challenging welding positions. 6G welding requires a high level of skill and expertise, involving the joining of two pipes at a fixed 45- degree angle. Our team of highly skilled and certified welders are equipped to handle this complex welding process, ensuring the structural integrity and longevity of the chilled water pipes.

Chilled water pipe rectification works will encompass a comprehensive assessment of existing pipelines, identifying area of concern, and implementing necessary repair or replacements. This process aims to optimize the efficiency of the cooling system, minimizing energy consumption and migrating potential system failures.

QATCO Qatar Service takes pride in its commitment to quality and precision, ensuring that the 6G welding and chilled water pipe rectification works result in a reliable and sustainable industrial infrastructure, meeting the highest standards of safety and efficiency.

Request A Quote

Share your details, and we’ll get back to you with a tailored estimate.